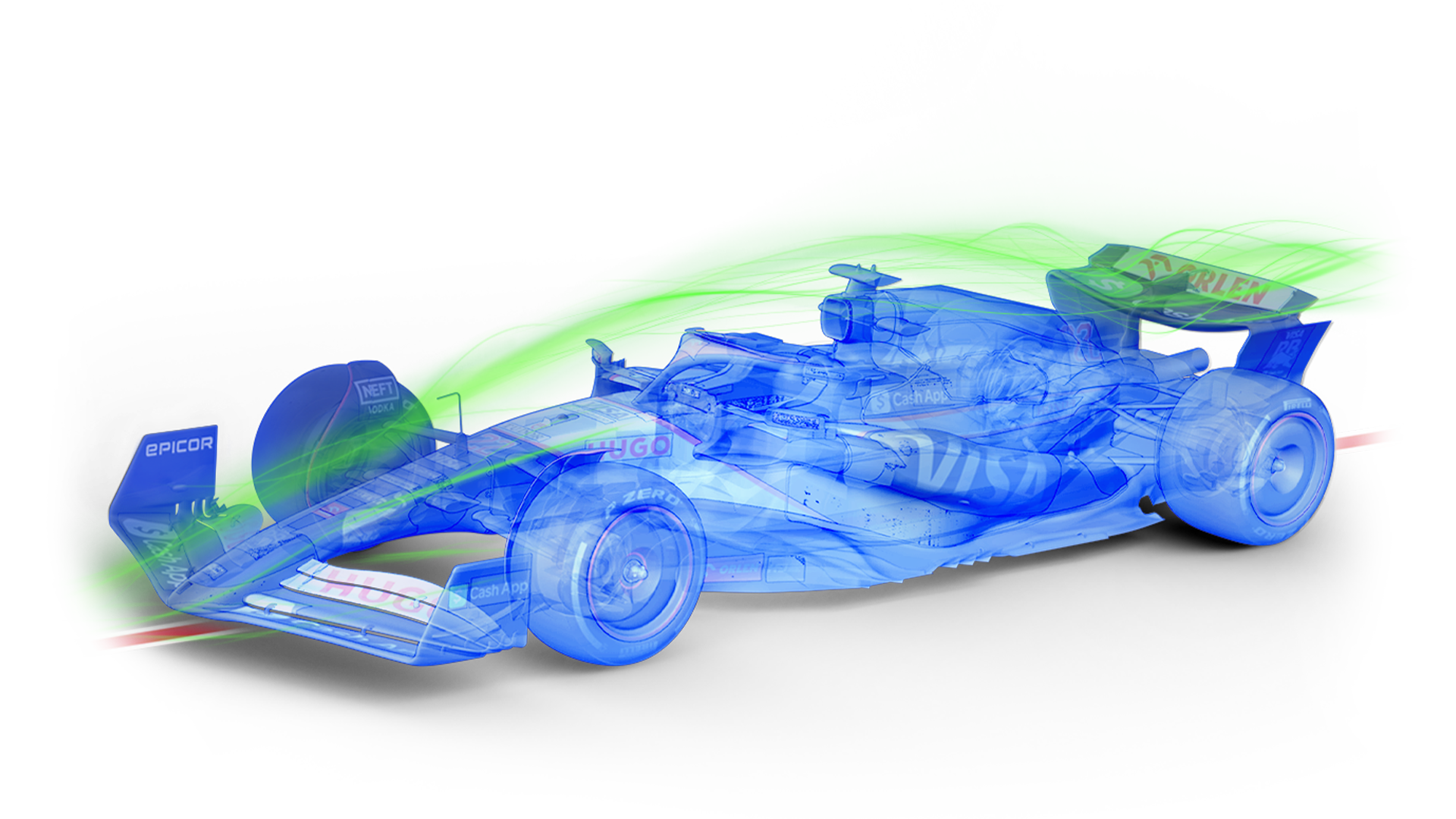

The floor of the car is now one of the most important elements of its aerodynamic package. The current cars generate what is known as “ground effect,” with the floor now responsible for producing 50% of the car’s total downforce. The other major elements in this area are the front and rear wings.

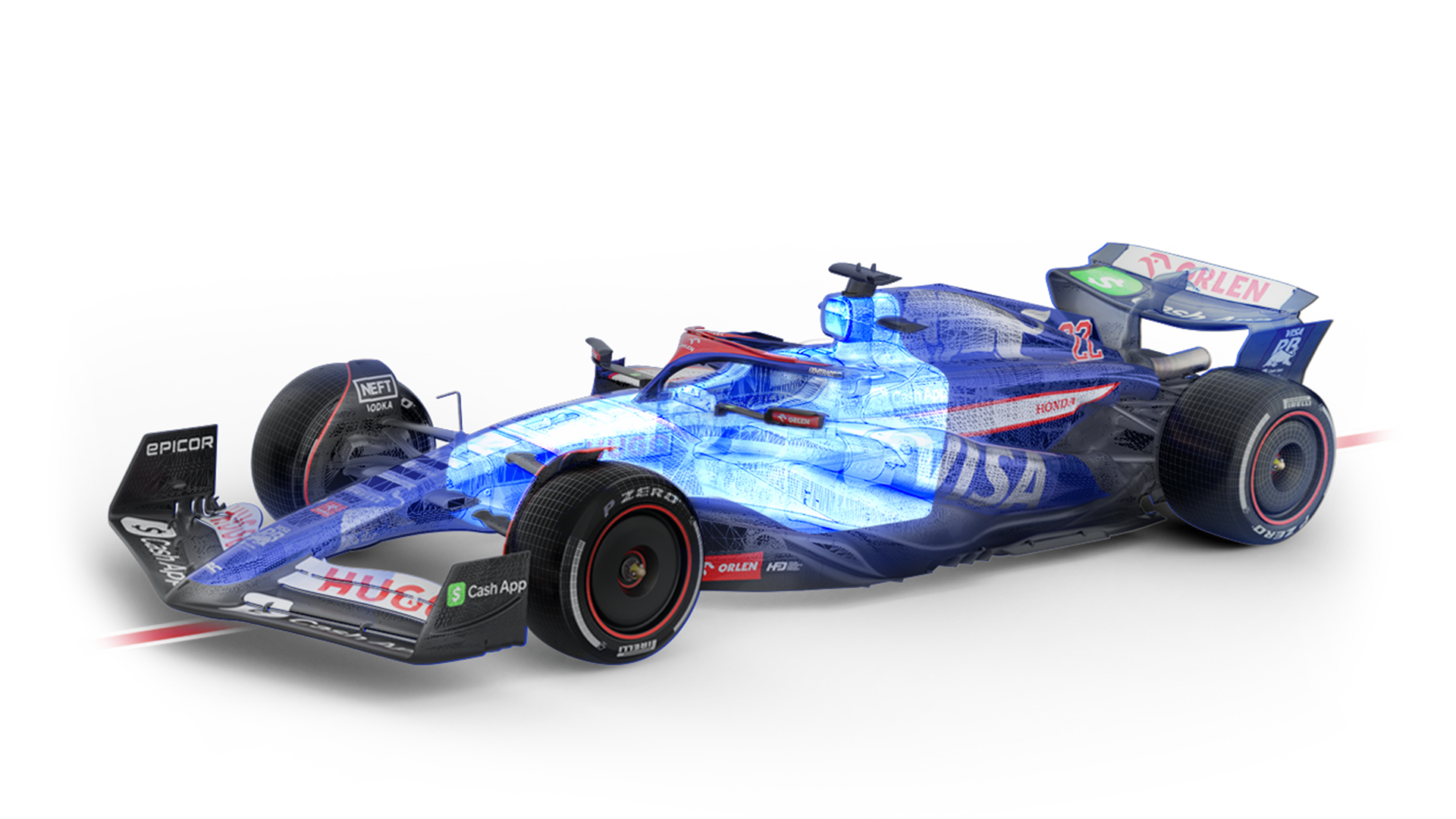

The main element around which the entire car is built. It has to be stiff enough to maintain its structural integrity but still have enough flex to adapt to torsional forces and this balance affects the car’s behaviour on track.

The idea behind the current Formula 1 cars, introduced in 2022, was to make for closer racing and a better show. A raft of major changes was introduced with the new design aimed at making overtaking easier, by reducing the amount of “dirty air,” the turbulent wash created behind the cars.

The power unit is a hybrid: a 1600cc internal combustion V6 turbo engine, along with two electrical units that recover energy from the turbine exhausts (MGU-H) and from the rear brakes (MGU-K). The longitudinally mounted gearbox has 8 forward gears, plus reverse.

The 2024 Pirelli range features five slick compounds going from the softest C1 to the hardest C5. To help with easy identification when the cars are on track, the chosen compounds each feature a different colour band: red for Soft, yellow for Medium and white for Hard. In the case of rain, there’s a choice of the green Intermediate or the blue Full Wet.

YUKI TSUNODA

DANIEL RICCIARDO

| POS | TEAM | POINTS |

|---|---|---|

| 1 | Oracle Red Bull Racing | 141 |

| 2 | Ferrari | 120 |

| 3 | McLaren | 69 |

| 4 | Mercedes | 34 |

| 5 | Aston Martin Aramco | 33 |

| 6 | Visa Cash App RB | 7 |

| 7 | Haas | 4 |

| 8 | Williams | 0 |

| 9 | Kick Sauber | 0 |

| 10 | Alpine | 0 |

| POS | DRIVER | POINTS |

|---|---|---|

| 1 | Max VerstappenOracle Red Bull Racing | 77 |

| 2 | Sergio PerezOracle Red Bull Racing | 64 |

| 3 | Charles LeclercFerrari | 59 |

| 4 | Carlos SainzFerrari | 55 |

| 5 | Lando NorrisMcLaren | 37 |

| 6 | Oscar PiastriMcLaren | 32 |

| 7 | George RussellMercedes | 24 |

| 8 | Fernando AlonsoAston Martin Aramco | 24 |

| 9 | Lewis HamiltonMercedes | 10 |

| 10 | Lance StrollAston Martin Aramco | 9 |

| 11 | Yuki TsunodaVisa Cash App RB | 7 |

| 12 | Oliver BearmanFerrari | 6 |

| 13 | Nico HulkenbergHaas | 3 |

| 14 | Kevin MagnussenHaas | 1 |

| 15 | Alexander AlbonWilliams | 0 |

| 16 | Zhou GuanyuKick Sauber | 0 |

| 17 | Daniel RicciardoVisa Cash App RB | 0 |

| 18 | Esteban OconAlpine | 0 |

| 19 | Pierre GaslyAlpine | 0 |

| 20 | Valtteri BottasKick Sauber | 0 |

| 21 | Logan SargeantWilliams | 0 |

Japanese Grand Prix Results

| POS | DRIVER | TIME |

|---|---|---|

| 1 | Max Verstappen Oracle Red Bull Racing | 1:54:23.566 |

| 2 | Sergio Perez Oracle Red Bull Racing | +12.535s |

| 3 | Carlos Sainz Ferrari | +20.866s |

| 4 | Charles Leclerc Ferrari | +26.522s |

| 5 | Lando Norris McLaren | +29.700s |

| 6 | Fernando Alonso Aston Martin Aramco | +44.272s |

| 7 | George Russell Mercedes | +45.951s |

| 8 | Oscar Piastri McLaren | +47.525s |

| 9 | Lewis Hamilton Mercedes | +48.626s |

| 10 | Yuki Tsunoda Visa Cash App RB | +1 lap |

| 11 | Nico Hulkenberg Haas | +1 lap |

| 12 | Lance Stroll Aston Martin Aramco | +1 lap |

| 13 | Kevin Magnussen Haas | +1 lap |

| 14 | Valtteri Bottas Kick Sauber | +1 lap |

| 15 | Esteban Ocon Alpine | +1 lap |

| 16 | Pierre Gasly Alpine | +1 lap |

| 17 | Logan Sargeant Williams | +1 lap |

| DNF | Guanyu Zhou Kick Sauber | DNF |

| DNF | Daniel Ricciardo Visa Cash App RB | DNF |

| DNF | Alexander Albon Williams | DNF |